Private Label vs. Contract Manufacturing

What is best for your business?

There is a lot of confusion regarding the subtle differences between contract manufacturing and private labeling. There are advantages and disadvantages to each method, and either can work well depending on the product and the requirements of the buyer. The end goal for both methods is the same, to procure a great product that customers will buy! Read more “Private Label vs. Contract Manufacturing”

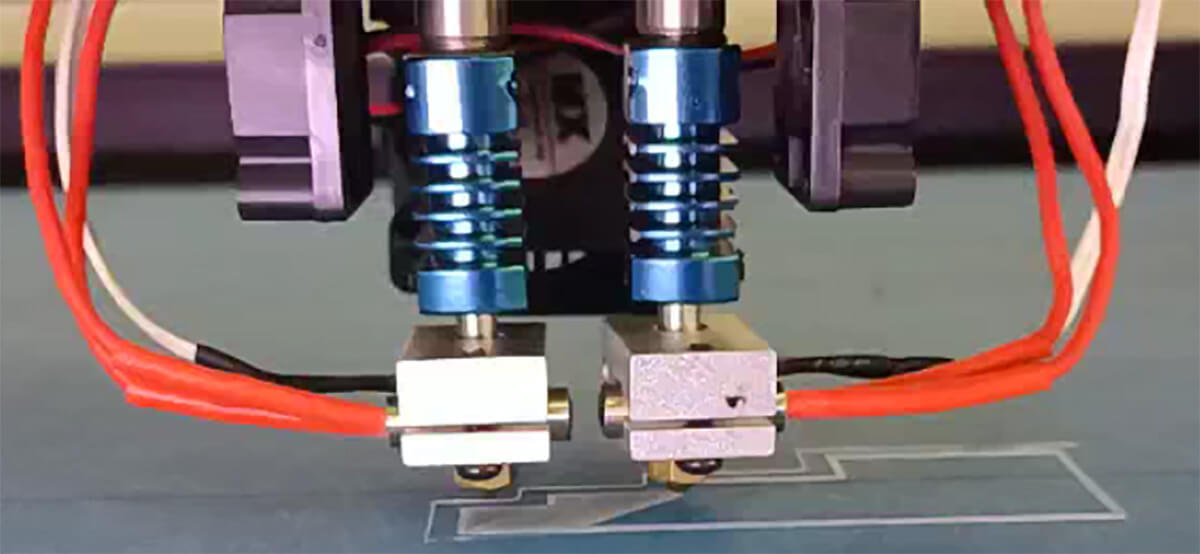

3D Printing vs. Plastic Injection Molding: How to Decide

3D printing, also known as additive manufacturing (AM), is a process that adds material to create an object. This is the opposite of CNC machining, which is subtractive manufacturing, as it removes material to create an object. Injection molding is neither additive or subtractive, since it simply takes existing material and “molds” it into a different shape. Read more “3D Printing vs. Plastic Injection Molding: How to Decide”

Outsourcing Production: What You Need To Know

Whether your facilities are at maximum capacity and you need to grow or you have a brilliant idea but no manufacturing, at some point people consider outsourcing their production. While you tackle the sales and marketing, a contract manufacturer (AKA “private label manufacturer”) can produce, assemble and ship your product.

Read more “Outsourcing Production: What You Need To Know”

End-to-End Solutions Provider

Assistance From Design to Fulfillment

RSP can assist our clients in every area of the product development cycle from design and engineering to prototyping to pre-production ramp-up, production, logistics and transportation, warehousing and order fulfillment. Let’s take a deeper dive into what each of these areas means and how RSP can help.

Read more “End-to-End Solutions Provider”

Contract Manufacturing FAQ: Answers from the Experts

Let’s Hear from the Sales Team

Frequently Asked Questions (FAQs)

Our clients, especially those with projects where multiple components are used in an assembly, ask us thoughtful, probing, and challenging questions every day. Often, these questions are very particular to a custom product we manufacture (e.g., “How will hot runners affect my plastic molding?”). Other times, the questions apply to almost any customer! Here is a sampling of some of those frequently asked questions that apply to most projects. Read more “Contract Manufacturing FAQ: Answers from the Experts”

Intellectual Property: How to Protect Your Valuable IP During Manufacturing in China

What Is Intellectual Property?

Put simply, your intellectual property (IP) is the idea, invention, or process behind your product, a creation of your intellect. This is a wide-ranging category that includes, among other things, trademarks, copyrights, patents, and trade secrets. The person who owns the IP has the power to decide how their IP is used and by whom. Read more “Intellectual Property: How to Protect Your Valuable IP During Manufacturing in China”