What Is Medical Device Manufacturing?

Medical device manufacturing involves the production of a wide range of equipment, instruments and other devices used in healthcare for diagnosis, treatment, monitoring and support of patients. This includes devices such as pacemakers, artificial joints, surgical instruments, imaging equipment, infusion pumps and much more.

The process of medical device manufacturing typically involves several stages, including design, prototyping, testing, regulatory approval and mass production. Manufacturers must adhere to stringent regulations and standards to ensure the safety, efficacy and quality of their products. This often involves rigorous testing, documentation and quality control measures throughout the manufacturing process.

Medical device manufacturing plays a crucial role in healthcare delivery, as these devices are essential for diagnosing and treating various medical conditions, improving patient outcomes and enhancing the quality of life for individuals worldwide.

What Are Medical Devices?

Medical devices are instruments, apparatuses, machines, implants or other similar items used to diagnose, prevent, monitor, treat or alleviate disease, injury or disability in humans. These devices serve a wide range of purposes across various medical specialties and healthcare settings. They include:

- Diagnostic equipment: MRI machines, X-ray machines, ultrasound scanners and blood glucose monitors.

- Therapeutic devices: pacemakers, prosthetic limbs and insulin pumps.

- Surgical instruments: scalpels, forceps, sutures and surgical lasers.

- Implants: artificial joints, stents and dental implants.

- Monitoring devices: electrocardiograms (ECGs), blood pressure monitors and pulse oximeters.

- Assistive devices: hearing aids, wheelchairs and mobility aids.

Medical devices can range from simple, low-risk products to complex, high-risk devices that require rigorous testing and regulatory approval before they can be marketed and used in clinical practice.

The Cost of Manufacturing Medical Devices

Manufactured medical products range from a simple orthotic shoe insert to diagnostic devices that monitor health. The elevated costs associated with manufacturing medical components stem from stringent requirements, certifications and services essential to uphold the safety standards and mitigate liabilities.

When it comes to products that save lives, ensuring you have the right contract manufacturer is critical. With extensive experience developing medical-grade products, RSP is poised to become your foremost partner in medical device manufacturing. Contact us today so we can discuss your project’s specifics, objectives and needs.

What Materials Do We Offer?

Working with RSP as your medical device contract manufacturer means you’ll have a partner that is experienced in working with the following materials:

- Medical-grade plastic

- Medical-grade silicone

- Medical device packaging

- Rubber

- Foam

- Glass

- Metal (including metal fabrication)

- Electronics

Although these are our main medical-grade materials, we can utilize other machinery and processes to help you get the product you need. Review our capabilities for more options or contact our team to discuss a customized solution.

What Is Plastic Medical Device Manufacturing?

In recent years, medical device manufacturers and the wider healthcare industry have been transformed by a growing demand for plastic. Plastic’s unmatched flexibility and versatility are employed across the healthcare industry, from microbiology and lab ware that use microplates and PCR tubes to housings for sterilizable systems.

The widespread use of plastic in the healthcare industry has improved the patient care experience, allowing healthcare facilities to help more people and save more lives. The medical device industry plays an integral role in innovating new products that can aid in novel procedures and in providing safer and more efficient medical devices for patient health. For example, an average medical procedure requires multiple devices, such as syringes, bedcoverings, endoscopic instruments and thermometers, all of which can be more efficiently made of plastic, and some of which could not be made without it.

Plastic medical device manufacturers like RSP work closely with the medical industry to make low-cost products that save lives. As an FDA Certified Manufacturer, RSP is able to fulfill orders to manufacture FDA-regulated devices used throughout the medical field. Our plastic molding and silicone molding facilities are also ISO 13485 certified for medical molding.

Medical Device Classes

In the United States, medical devices are categorized into three main classes based on the level of risk associated with their use. These classes are defined by the Food and Drug Administration (FDA) and are used to determine the regulatory requirements for bringing a medical device to market.

Class I: These are low-risk devices that are subject to the least regulatory controls. They include simple devices like tongue depressors, elastic bandages and bedpans.

Class II: These are moderate-risk devices that require greater regulatory controls to ensure their safety and effectiveness, including infusion pumps, surgical gloves and diagnostic test kits.

Class III: These are high-risk devices that are subject to the most stringent regulatory controls due to the potential risks associated with their use. Examples include implantable pacemakers, heart valves and deep brain stimulators.

There are different regulatory requirements for each class of product, so the medical device manufacturer you choose should have prior experience and facilities capable of meeting the necessary standards.

Medical Device Manufacturing Services

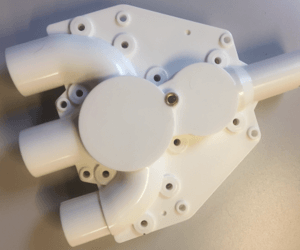

RSP’s experience enables us to be a premier partner to manufacture small-, medium- and large-volume medical products for OEMs. Our team has the experience you need to design, prototype and manufacture high-quality medical products. We can even contribute to the medical manufacturing process by simply supplying components, subassemblies or full turnkey assemblies.

Plastic Medical Product Examples

- Components for MRI machines

- Blood circulation stimulators

- Light therapy devices

- Electronic motivational device assemblies

- Foot sensor platforms for machine exoskeletons

- Ventilator masks

- Swabs and packaging

- Compression socks

- Sample kits for patients

Medical-Grade Silicone Component Applications

If you need medical-grade silicone molding for your device or project, make RSP your supplier. Our facility is ISO 13485 for medical molding, and we also are FDA certified. Our machines range from 250 to 400 tons, and we have the capacity to produce small and large quantities. In the past, we have provided many user-interface keypads for medical equipment found in doctors’ offices and hospitals. We also produce simple gaskets and seals.

Silicone Product Examples:

- Finger toothbrush

- Respirator mask

- Children’s nasal aspirator

- User interfaces / keypads

- Gaskets

Need to know whether we can manufacture a specific piece of medical equipment? Contact us to find out more about our medical plastic manufacturing capabilities!

How We Package Your Medical Devices

Along with our FDA certification, we are excited to announce additional equipment has been added to our facilities. Our new pouch-sealing machines will be used to package high-quality medical products. These new machines help manufacture medical-grade plastic supplies as they heat-seal pouches to ensure items inside cannot be contaminated or lost. It not only keeps everything together but also seals quickly and consistently to 100 percent prevent the transfer of potentially dangerous pathogens to the items inside.

Learn more by heading over to our medical packaging post for more in-depth details, or visit our contract product packaging services page.

How to Find the Right Medical Device Manufacturer

Finding the right medical device contract manufacturer is critical to not only the quality but also the success of your product. It’s important that communication and requirements are clearly understood and that the client and the manufacturer are both comfortable with the relationship. RSP offers you the assurances and has the certifications you need to make sure that the materials, processing, packaging and testing are all done correctly for safety and optimal performance. Contact RSP today to have us join your team as a contract manufacturing partner for your medical product needs.

Request a Quote

If you are like any of our customers, you think about your product 24/7. You dream of how it will change the market or maybe you’re creating a brand new market. But when it comes to executing the product, you’ve realized you need some help. And that’s where we come in.

Fill out the information below so we can get a good understanding of what you may need from us. We will respond as quickly as possible to your request, however, please allow at least 24 business hours.

Looking for immediate assistance? Call our sales professionals directly based on the timezone that works best for you. English speakers are available at all locations.

USA: +1-866-329-1804 - UTC-6: Central Standard Time

China: +86-0755-8366-3414 - UTC +8: China Standard Time