Silicone Keypad Manufacturer

RSP, headquartered in Milwaukee, WI, manufacturers rubber keypads also known as silicone keypads, which are ideal for a range of products. The average person comes in contact with silicone keypads, also known as elastomeric keypads, almost every single day. Because of their low cost, flexibility of design and reliability, silicone keypads are used in a variety of industries, including medical, marine, and military, in addition to consumer applications, such as TV remotes and electronic games.

Additional silicone rubber keypad features include:

- Resistance to both high and low temperatures (-55° C to 250° C)

- Minimal noise generation due to soft and elastic contact structure

- Minimal abrasion and high resistance to sulfur dioxide and oxidation even in heavy humidity

- Designed for snap ratio and tactile feedback

- Translucent color which is excellent for backlighting

- Multi-color designs easily accommodated

- Water and contamination resistant

- Coating options for increased durability chemical and environmental resistant

Video: Laser Etching Process

Designing a Silicone Keypad with RSP

As mentioned above, there are many favorable qualities to use silicone keypads. As a manufacturer of silicone, which can be utilized in so many applications, RSP offers several levels of involvement when it comes to your silicone keypad project. Our team also uses quality assurance and quality control measures throughout the process to ensure each keypad is completed to your standards.

Medical Devices & Plastic Molding - ISO 13485

A lot of the clients we work with create products for the medical industry. RSP has a quality management system in place to provide services that meet FDA and other regulatory requirements. The quality system, known as ISO 13485, is recognized internationally and ensures that every step of manufacturing is documented and performed correctly. A full service global contract manufacturer, specializing in plastic molding, we are ISO 13485 certified and take the regulatory requirements very seriously.

No matter where you are in your project, RSP can help:

Haven’t started designing the keypad?

Supply RSP with dimensions and desired snap ratio for a full design

Not sure what snap ratio is or what ratio you are looking for? We can walk you through it.

Already have the keypad designed?

RSP can review the design and offer suggestions/tweaks for improving the function, fit and feel.

Need to customize a keypad for an already designed product?

Supply us with the assembly model of the product and we will fully customize a keypad based on your requirements.

Have a keypad you love from another product of yours?

Send us the reference keypad for re-engineering and we’ll match the function and feel.

Creating Silicone Rubber Keypads

Much like plastic molding, silicone keypads can be very adaptable and multifunctional. In terms of adaptability, raw silicone can be made with a specific hardness, color and level of transparency. Each of these characteristics are customized per a customer’s needs.

Once the raw material is created with the desired hardness, color and transparency, it will go through one of two machine types -- injection molding or compression molding machines. Due to cost constraints, most keypads and gaskets are compression molded.

To give you a visual, think of a compression mold as a giant waffle maker. There is a top half and a bottom half which compress a carefully cut and weighed portion of silicone material. Once the mold is preheated to the correct temperature, the mold is then closed under extreme pressure (150 - 250 tons).

During the molding and compression time when the tool is closed, the silicone fills up the entire mold cavity and is then vulcanized. Vulcanizing is the hardening process; molecules are transformed into the desired shape. Once the tool is opened, the machine operator uses compressed air to remove the components from the tooling.

Video: Think of this machine as a giant waffle maker to compress the silicone rubber.

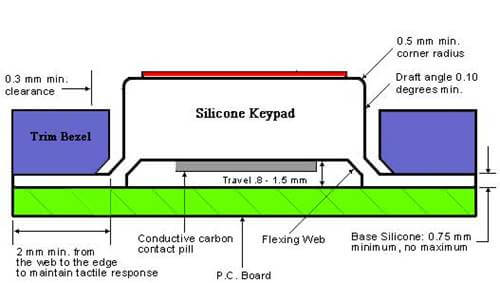

Designing for Snap Ratio & Tactile Feedback

As mentioned above, being able to design silicone keypads for specific snap ratio and tactile feedback is one of the many favorable qualities of silicone. Much like membrane switches, it is important for a user/operator to recognize when he or she has fully pressed a key. This action is done when the operator depresses the key which collapses the webbing and connects the contact area on the bottom of the key to a circuit or mechanical type key below, then once pressure is removed the webbing returns to its neutral position. The differential between the pressure combined with the movement creates tactile feedback and can be designed optimally by design engineers using the proper snap ratio.

To better understand snap ratio, it is important to know the ratio is determined by actuation force (the force required to collapse the membrane/web of a rubber switch, also referenced as F1 in the formula below) and contact resistance (F2).

F1 - F2

-----------

F1

The recommended snap ratio to maintain is 40% - 60%; if dropped below 40%, the keys will lose tactile feel but have an increased life. Loss of tactile feel means the user will not receive a 'click' feedback during actuation. Since most applications require a positive tactile feel and a long life, it is best to design for an actuation force of 125 - 150 grams and an accompanying snap ratio of 40% - 60%.

Since silicone is an adaptable material, the membrane shape and size can be designed to achieve a variety of actuation forces and tactile responses. Additional customization for your silicone rubber keypad can be achieved by changing the contact stroke, actuation force, key shape and material hardness. For instance, to create taller or wider keys, the keypad must to be designed with a higher actuation force.

Making a Contact

In order to make a proper connection with the printed circuit board (PCB) or printed circuit, it is necessary to use a conductive carbon contact. The contact can be printed carbon or a pre-formed carbon piece known as a “pill”. Printed carbon contacts are sufficient for most constructions. A conductive carbon contact pill can also be used but adds some cost. Carbon pills are known for long life (>10 million actuations) and low resistance (<100W). Additionally, the pills come in a variety of shapes but are usually circular with diameters ranging from 1.5 - 10 mm and thickness from 0.4 0.6 mm.

Epoxy Coating

RSP’s engineering team has developed a proprietary method for applying an epoxy coating to silicone keypads that improve quality, reduces scrap, and lowers the cost! Epoxy coating is used to provide a glossy finish while also protecting printed legends and markings on the keys. The previous methods used for epoxy coatings involved dip coating or using pill droppers to deposit the epoxy on each key. This resulted in a high rate of process failure due to the unpredictable nature of the epoxy. Our unique new epoxy blend, combined with our proprietary method, has been proven to reduce the scrap rate and improve the aesthetic finish with consistent, precise application.

Video: We have many coating options to increase durability and to make the product resistant to chemicals and environmental factors

Additional Design Components to Consider:

Printing

- Printing is the most common method of marking silicone.

- This process does not limit the number of colors available.

- The arc of the key top determines how far printing must be set back from the edge of the key.

- There are several options for improving legend life:

- Plastic Key Caps: Custom molded clear plastic is adhered over the legend or molded into the rubber.

- Oil or Epoxy Coating: Coating is deposited on the top surface of the key over printing; available in matte, semi-gloss or gloss finish.

- Drop Coating: Drop coating can be hard or flexible. It adds a glossy layer over the key top. It cannot be used on some keys with sharp angles. Hard coatings are subject to cracking if the key has large surface areas.

- Parylene Coating: Offers the highest level of protection for a non-plastic coating. Parylene bonds to the rubber at the molecular level.

Laser Etching

- Laser etching is especially well suited for applications where the keypad is backlit.

- Etching typically involves three production steps.

- 1) Translucent rubber (any color) is sprayed with a translucent base coat ink which will be the legend color that is visible to the user.

- 2) Rubber is sprayed with an opaque top coat ink, which will be the overall color of the keypad.

- 3) The top coat of ink is laser etched away using high speed etchers to reveal the base coat.

- Alternatively, you can decide to use a single translucent or opaque rubber ink and laser etch the legends revealing the color of the rubber that is used.

Plastic Key Caps

- The longest lasting legend type is custom molded plastic.

- Many of the first cell phones on the market were designed with plastic keys over rubber.

A common problem with rubber keypad design is the rocking action that can occur when a key is pushed. Rocking action can reduce the life of the keypad, make actuation difficult for the user and cause other problems. The following suggestions will assist in reducing this problem:

- Add stabilizing posts on base of key

- Keep keystroke as near 0.8mm as possible

- Keep web length to a minimum

- Keep web angle close to 40°

- Actuation force of 80 - 150 grams for keys 10 - 15 mm high

- Actuation force of 150 - 175 grams for keys 15 - 25 mm high

- Return force should be set at 30-35 grams to ensure that keys do not stick

For any design, calculate the minimum key height as follows:

Keypad Base Thickness + Bezel Thickness + Stroke of Key + 0.5mm = Min. Key Height

When considering a PCB design, the environment in which the silicone keypads are used must be considered to ensure that the complete switching unit is reliable. The choice of plating is the most critical factor when designing.

- Gold plating over nickel plating:

- Preferred choice for board design.

- Recommended layer of 30 - 50 microns of gold and 100 - 200 microns of nickel giving a contact resistance of <100W.

- Nickel plating:

- The next best option and the most commonly used.

- Nickel offers good reliability and is more cost effective than gold over nickel.

- A plating level >200 microns is recommended for the best overall performance.

- Tin/lead solder boards are not recommended.

When designing shorting pads, always attempt to insert as many shorting pads as possible to increase switch reliability and ensure the pad size is never smaller than the carbon pill by a minimum of 1.25 times.

Note: Keypads can also be used with flexible printed circuits and can be made of polyester or copper.

Machine & Material Specifics:

Looking to see what machines, materials and inspection devices we use?

Request a Quote

If you are like any of our customers, you think about your product 24/7. You dream of how it will change the market or maybe you’re creating a brand new market. But when it comes to executing the product, you’ve realized you need some help. And that’s where we come in.

Fill out the information below so we can get a good understanding of what you may need from us. We will respond as quickly as possible to your request, however, please allow at least 24 business hours.

Looking for immediate assistance? Call our sales professionals directly based on the timezone that works best for you. English speakers are available at all locations.

USA: +1-866-329-1804 - UTC-6: Central Standard Time

China: +86-0755-8366-3414 - UTC +8: China Standard Time