Tactile feedback significantly enriches the user experience of equipment. It serves many purposes: confirming button actuation, preventing errors, facilitating accessibility for the visually impaired and ultimately heightening overall user satisfaction.

RSP’s expertise in tactile feedback technology has enabled us to become leaders in the field. With more than 40 years in the membrane switch industry, RSP has solidified our expertise in the design and construction of tactile dome arrays.

What Are Tactile Dome Switches and Buttons?

Tactile dome switches, also known as tactile buttons, are individual dome-shaped structures integrated into membrane switches. Each dome contains a conductive pad at its base, which makes contact with the circuit traces on the membrane when the user compresses the dome.

They play a crucial role in providing tactile feedback to users. When a user presses a button, the dome collapses, creating a tactile sensation or “click” that confirms the actuation of the switch. This feedback is essential, as it gives users a physical confirmation of their actions, enhancing their experience by providing a responsive and intuitive interface. Additionally, the tactile feedback helps users operate the membrane switch more accurately, preventing accidental presses and errors.

Tactile dome switches are constructed using durable materials to ensure longevity and reliable performance. The domes are typically made of stainless steel or polyester, chosen for their resilience and ability to withstand repeated compression cycles without deformation. The conductive pads integrated into the base of each dome are usually made of materials such as silver or carbon, providing excellent conductivity for reliable electrical contact.

What Are Metal Domes?

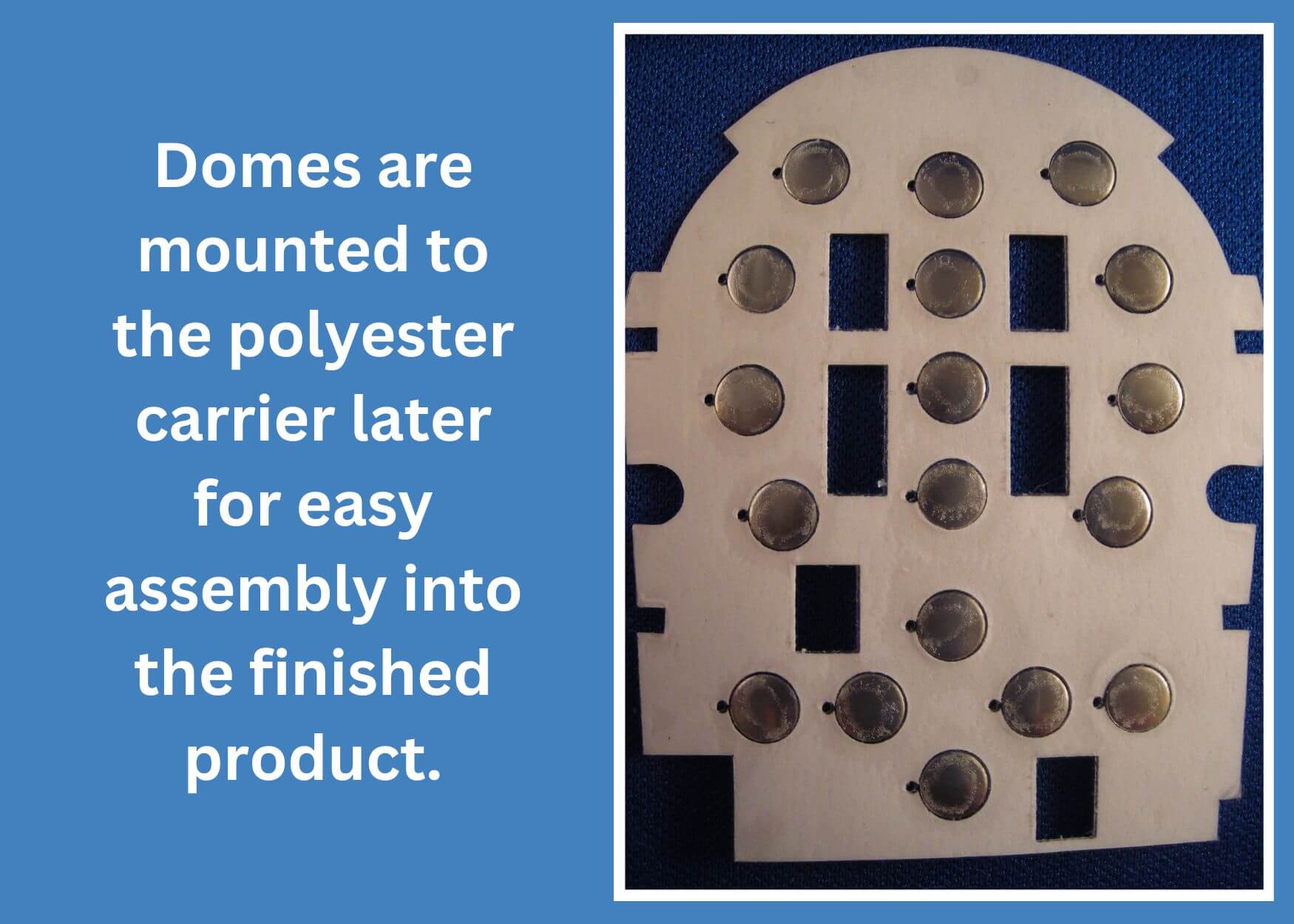

Metal dome tactile switches are a specialized type of assembly used in the manufacturing of various electronic devices, including printed circuit boards (PCBs), membrane switches and other user-input devices. These dome arrays consist of multiple individual metal dome switches arranged in a predetermined pattern or array on a substrate.

In PCBs, metal dome arrays are often incorporated into the design to provide tactile feedback for user interface elements such as buttons or switches and replace board mounted switches. In membrane switch construction, metal dome arrays are frequently utilized to create responsive and tactile buttons or keys. The dome arrays are positioned between the top membrane layer and the bottom circuit layer of the membrane switch assembly. When pressure is applied and the metal domes collapse, a tactile response is created to signal user input.

What Are the Benefits of Dome Arrays?

There are many benefits to using dome arrays in your product, including enhancements to user experience, durability, and design and functionality.

- Tactile Feedback: When pressed, dome arrays offer a satisfying click or snap sensation.

- Durability: Metal dome arrays are highly durable and capable of withstanding millions of actuations without losing their tactile properties.

- Space Efficiency: Compared with traditional mechanical switches, metal dome arrays offer a more compact and space-efficient solution. Their low profile allows for the design of thinner and lighter electronic devices, making them ideal for applications where space is limited or weight reduction is a priority.

- Cost-Effectiveness: Metal dome arrays are cost-effective compared with alternative tactile feedback solutions such as mechanical switches or capacitive touch sensors.

- Customization: Metal dome arrays can be customized in terms of shape, size, actuation force and tactile response to meet specific design requirements. This flexibility allows designers to create tailored user interfaces that align with the aesthetic and functional needs of their products.

- Easy Integration: Metal dome arrays are easy to integrate into the design of PCBs or membrane switches, requiring minimal additional components or assembly steps. This simplifies the manufacturing process and shortens time to market for electronic devices, resulting in cost savings and increased efficiency.

Types of Dome Arrays

Metal dome arrays come in various types, each offering unique features tailored to specific applications.

Four-Legged Metal Domes:

Domes have four legs that attach to the circuit layer, providing crisp tactile response. These versatile dome arrays are widely used in various applications.

Metal Dome with Dimple:

Adding a dimple to the center of the dome can enhance the tactile feel by concentrating the force side of the dome.

Triangle Metal Domes:

Triangular in shape, they provide a distinct tactile feel.

Round Metal Domes:

They are used in membrane switch construction with force evenly distributed across the dome.

Dual-Stage Metal Domes:

These domes offer two distinct force levels, providing different tactile responses during the initial press and then a different feel when the actuation force is higher.

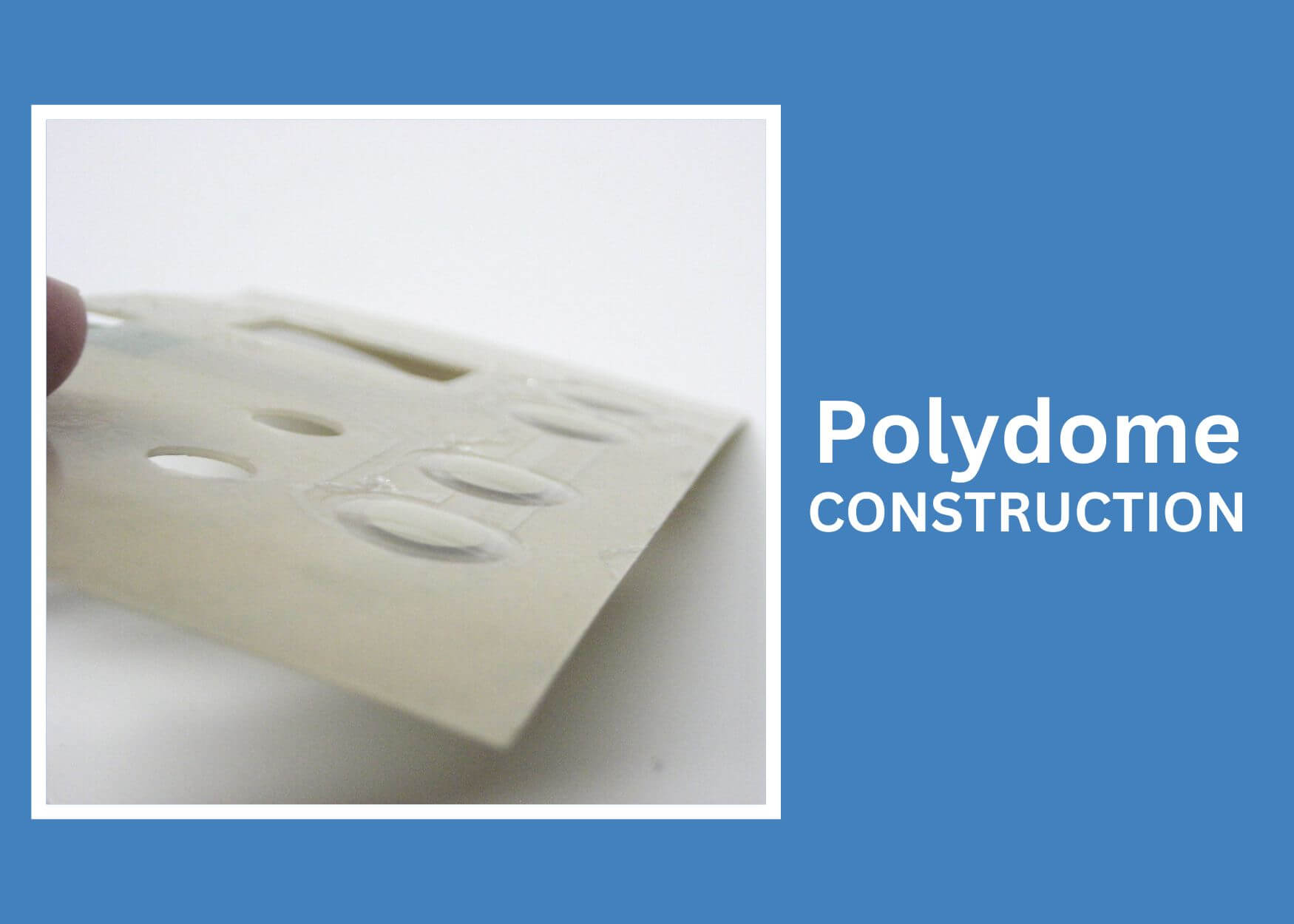

Polyester Embossed Domes:

Commonly known as poly-domes, this cost-effective solution creates the dome shape by embossing a polyester layer in the construction. It offers good tactility and can actuate a switch, or the underside of the polyester layer can have a printed conductive ink that completes the circuit.

Customized Metal Domes:

Customization offers a variety of shapes, sizes, force characteristics, etc.

Metal Dome Array Uses

Metal dome arrays are useful across a wide range of industries due to their versatility, durability and tactile feedback properties. Some of the industries where metal dome arrays are commonly used include:

- Consumer Electronics: Metal dome arrays are extensively used in consumer electronics such as smartphones, tablets, remote controls, gaming devices and wearable technology.

- Automotive: Metal dome arrays are found in automotive applications including dashboard controls, infotainment systems, steering wheel controls and keyless entry systems.

- Medical Devices: In medical devices such as patient monitoring systems, diagnostic equipment and handheld devices, metal dome arrays are used to provide tactile feedback for user-input interfaces. Their precise actuation and long-term reliability are critical in the medical field.

- Industrial Control Systems: Metal dome arrays are employed in industrial control panels, machinery interfaces and equipment controls.

- Appliances: Metal dome arrays are used in household appliances including microwave ovens, washing machines, dishwashers and coffee makers. They ensure responsive and reliable operation of control panels and user interfaces.

- Industrial Equipment: Metal dome arrays are employed in various industrial equipment such as manufacturing machinery, process control systems, and test and measurement devices. Their tactile feedback facilitates user interaction and control.

Dome Arrays for Any Application

Choosing the right dome is very important to provide the user the correct amount of feedback. Other considerations when choosing a metal dome or dome array is the environment the interface is used in. In some settings (like on a fire truck or in heavy industry) users wear gloves, so a larger dome and higher tactile feedback may be needed to ensure the user knows the switch has already been activated.

Interested in incorporating a metal dome array into your design to improve tactile feedback and enhance user experience? Contact RSP today to learn more about how we can help you make your idea a reality.