What is best for your business?

There is a lot of confusion regarding the subtle differences between contract manufacturing and private labeling. There are advantages and disadvantages to each method, and either can work well depending on the product and the requirements of the buyer. The end goal for both methods is the same, to procure a great product that customers will buy!

What is Contract Manufacturing?

Contract Manufacturing is a form of outsourcing in which a business works with an outside manufacturing firm to create a finished product. In contract manufacturing, the buyer approaches the manufacturer to work on the design and manufacturing of a product per spec. While the manufacturer will often offer advice and expertise, it is the buyer who retains final say, responsibility and control over the product produced. If you are looking for contract manufacturing services, contact us by clicking the button below!

GET A QUOTE FOR CONTRACT MANUFACTURING

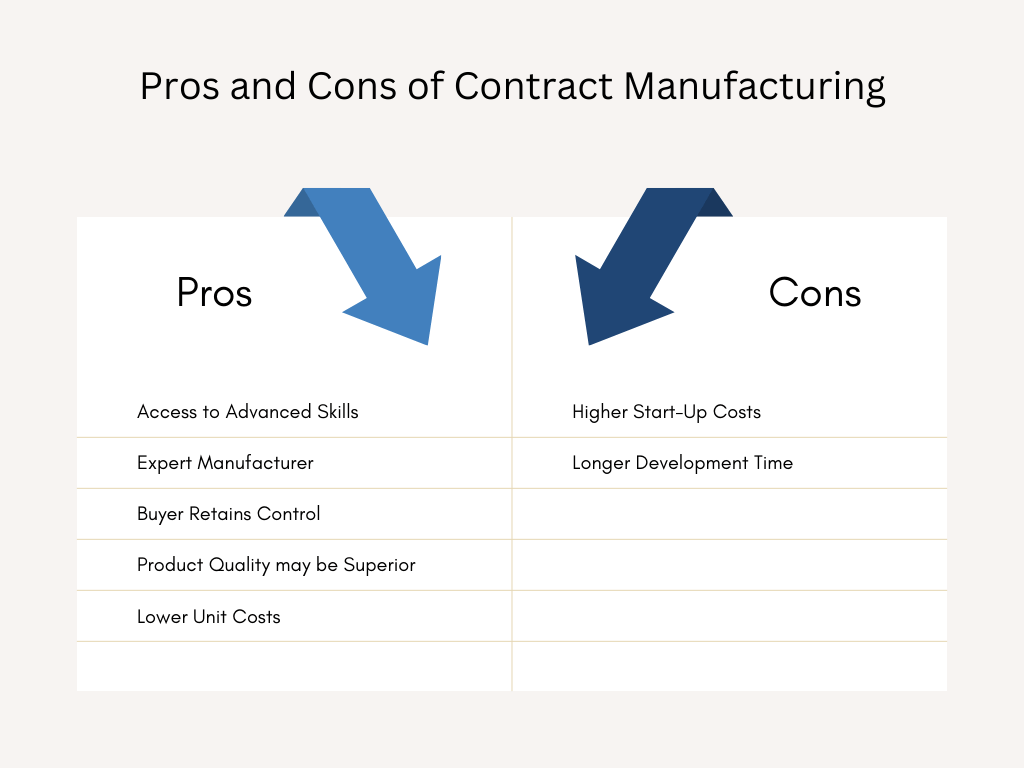

Contract Manufacturing Advantages & Disadvantages

Advantages

- The relationship gives the buyer access to advanced skills. The manufacturer is an expert in making a product and can improve upon it.

- The buyer retains control over the product, including image, branding and packaging.

- Product quality may be superior, as the buyer sets the standard and testing methods.

- Lower unit costs may be lower. Since the buyer is contracting the manufacturer, they can typically negotiate market pricing that is lower than private label options.

Disadvantage

- Higher start-up costs and longer development time.

What is Private Label Manufacturing?

Private label manufacturing, also known as white labeling, is when a company buys and brands products that are pre-manufactured by a third-party supplier, usually with minimal or no customization. Under a private label agreement, the manufacturer owns the entire production process and commonly provides the same or similar products to multiple companies. The hiring company essentially acts as a distributor, reselling these products under its own brand.

While there might be some minor adjustments, such as packaging and branding, the core product remains largely unaltered. The hiring company applies its brand name, logo and packaging to the product, marketing and selling it as if it were an original creation. Private labeling is characterized by its simplicity and rapid market entry, allowing companies to expand their product offerings swiftly without the need for extensive product development or manufacturing capabilities.

This business model offers flexibility and efficiency, enabling companies to focus on marketing, distribution and building their brand identity while relying on the expertise of the manufacturer for production. Private label manufacturing has become a strategic choice for businesses seeking a streamlined approach to product diversification and market entry.

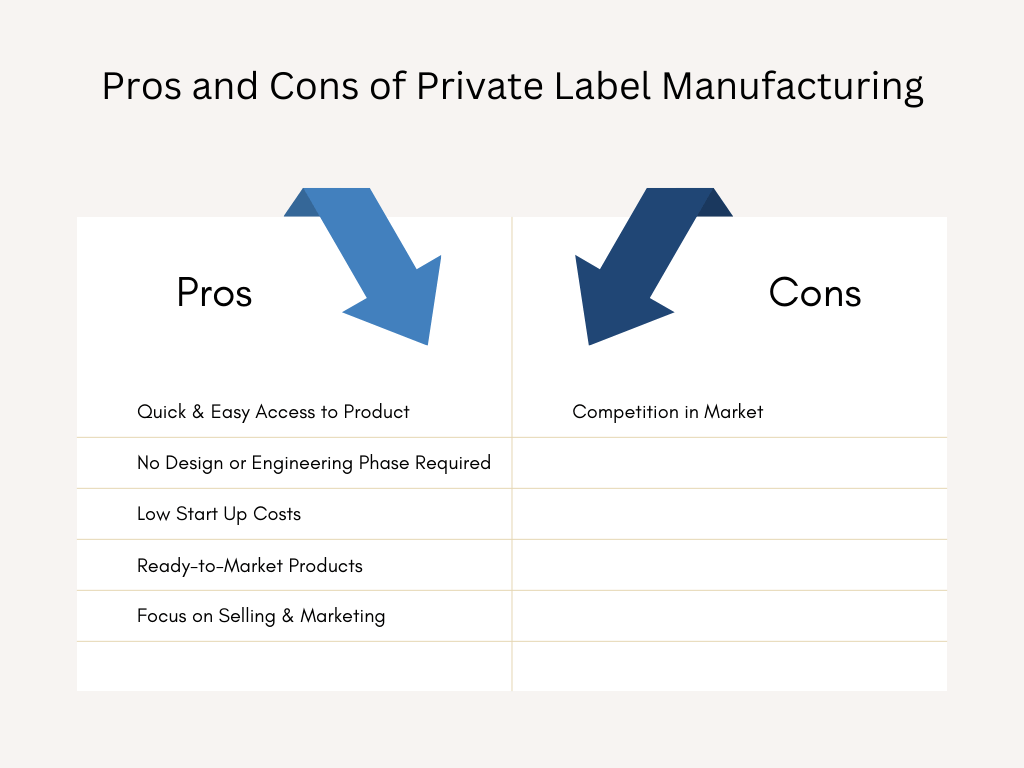

Private Label Advantages & Disadvantages

Advantages

- Quick and easy access to product: No design, engineering, tooling or ramp-up phase required.

- Low start-up costs: Product is ready for market.

- Laser focus: Having a ready-to-market product helps the buyer focus on selling and marketing.

Disadvantage

- Competition in the market: Multiple channels might be selling the same product.

There are pros and cons to contract manufacturing and private labeling. It is important to understand the implications of each method. Contract manufacturing ultimately provides the buyer more control over the product and a price advantage on each unit produced.

Contract Manufacturing vs. Private Label: What Is Best for Your Business?

There is a lot of confusion regarding the subtle differences between contract manufacturing and private labeling. There are advantages and disadvantages to each, and either can work well depending on the product and the requirements of the buyer. The end goal for both methods is the same, to procure a great product that customers will buy!

Should you opt for contract manufacturing or private labeling? The choice hinges on your business needs. Before making a decision, reflect on these key questions:

- Involvement: How hands-on do you want to be in the product design and manufacturing process?

- Budget: What’s your budget for product development, start-up and tooling costs?

- Time to Market: Are you aiming for rapid brand growth or swift expansion of your product line?

- Differentiation: Can you compete with a standard offering, or does your brand thrive on creating unique value for customers?

- Supplier Relationships: Is a long-term contract manufacturing partner, deeply invested in your unique product, more advantageous than a private label partner juggling various clients and their diverse needs?

Choosing contract manufacturing is ideal for businesses ready to make a bold market entry, introducing something fresh and compelling. The decision lies in aligning your strategy with the right manufacturing approach.

How to get a Product Manufactured?

Now that you’ve decided between contract manufacturing and private labeling, it’s time to reach out to find a manufacturing partner for quotes. Not sure what to ask? Check out this post to help you prepare questions to ask a contract manufacturer, and contact the experts at RSP to discuss any questions or concerns you may have. We can work with you to find which method of production your business requires. We look forward to helping you manufacture your dream product.

Interested in learning more about what we can do? Visit our capabilities page.