What We Do To Ensure High Quality All The Time

RSP utilizes testing equipment to qualify the products we manufacture during design and production. Read on to learn more about some of the equipment we use to ensure our customers’ products work for the environment they will be used in.

Mistral Testing – membrane switches

Mistral test stations are used to test 100% of the switches we produce. Mistral is well-known in the industry for high-quality, efficient testing of membrane switches. When testing a membrane switch, the connector on the end of the tail is plugged into the tester. Then each key or button is pressed, and the software maps out and learns the key and LED schematics. The software will read out the resistance value of each button and the ohms generated by each LED, and detects the resistance levels. The software also generates a report, which shows the average resistance and ohms of each button or LED tested during the batch. These results help RSP confirm that the product is functioning properly so that it is ready for our clients to integrate into their assembly seamlessly.

Pressure Chamber – outdoor fishing products

RSP uses a pressure chamber to test products used underwater. One of our customers makes a robotic fishing lure that is used at sea, so the product needs to work at depths of up to 200 feet. It is important to test the lure during production to be sure all the seals work properly in the field when the product is submerged in the ocean or other large body of water. In order to test for this environment, RSP used a pressure test chamber. For this test, the product was placed into a chamber filled with water that simulates the pressure at a 200-foot depth. Through this testing, RSP worked with the client to modify and improve the product’s design to provide optimal function under these conditions. RSP continues to perform these tests for all new production runs to ensure consistent results with the electronic lure.

Environmental Chambers – outdoor product testing

Similar to the pressure chamber, RSP uses a temperature and humidity chamber to test many products by replicating the environment in which the product will be used. RSP can accelerate the testing by automatically cycling the environment to ensure it will stand up to the elements in the field. There are also advanced chambers that RSP can utilize for more complex testing of rain, wind, UV sunlight exposure and more. For example, RSP makes a product for the roofing industry that requires advanced testing for regulatory approval in the US. These tests help to pinpoint potential design flaws and prove the product will stand up to the actual environment it will be used in. Many products require this type of testing based on industry-specific regulations. It is important to understand your industry’s requirements so that your manufacturer can test appropriately. RSP can assist you in finding the proper testing company to perform these extreme tests.

3D Scanning – design process and quality control

3D scanning is a process that uses a specialized machine to scan a physical product and create a 3D rendering of it. This allows RSP to confirm specific dimensions of a product and determine whether it was made within acceptable tolerances. It also allows you to review your product’s critical dimensions to show that the manufacturing process is meeting them. 3D scanning is also useful for companies that are looking to reproduce a product that they do not have a 3D electronic model of. In that case, the company can use a 3D scanner to scan a sample of the old part and get 3D renderings of the product in a quick but accurate way.

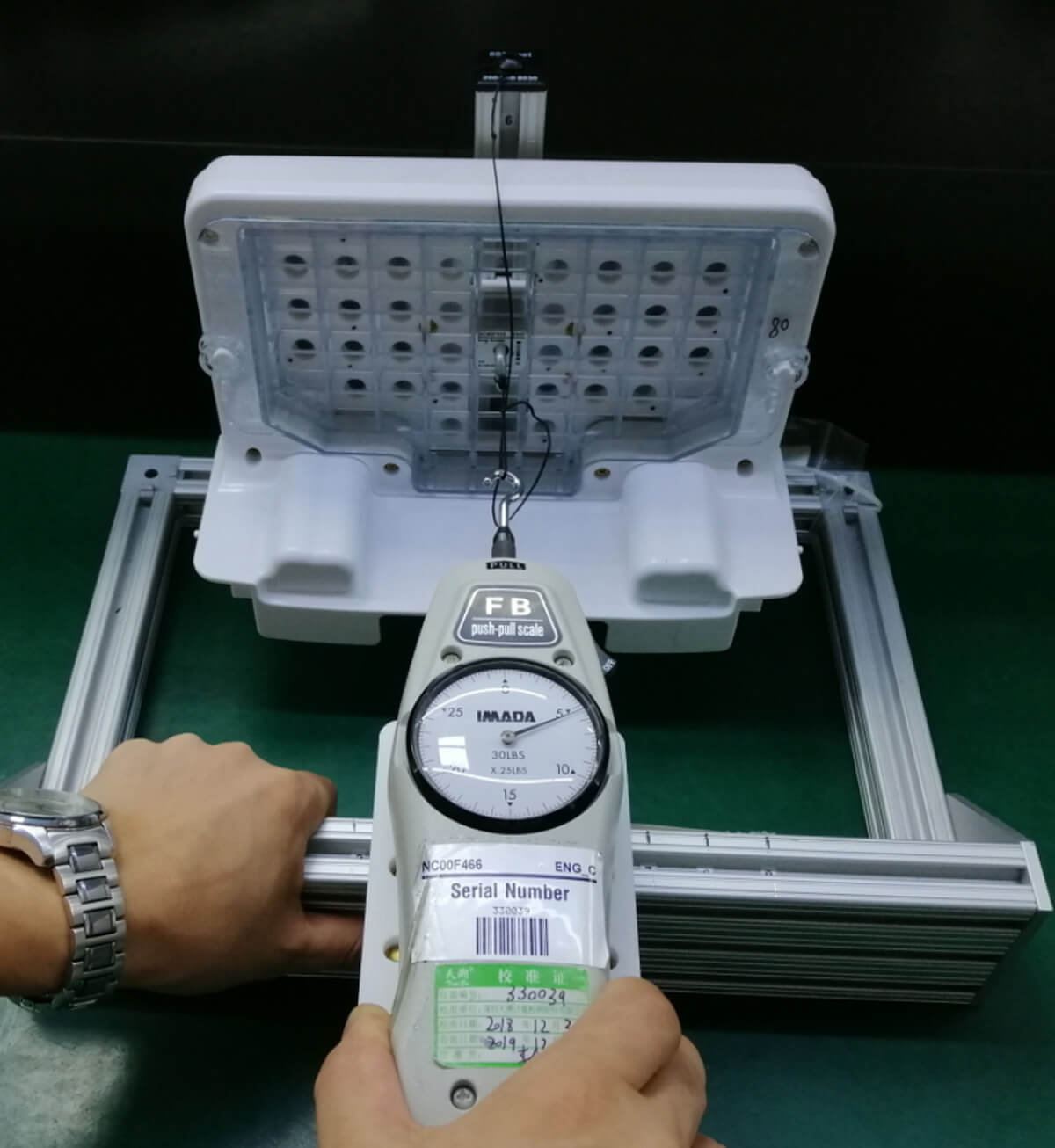

Keypad Life-Cycle Testing – membrane switches and silicone keypads

If you have a product that uses a keypad, you may need to know how long the product will last. How many button pushes can the product withstand before failure? This is a common question in the industry for silicone keypads and membrane switches. RSP has life-cycle testing equipment that continuously cycles key actuation over a period of time, generally until failure. This test will let you know how long the keypad will last. RSP has a vast amount of experience designing and producing silicone keypads and membrane switches for long life (more than 1 million actuations), so if you need assistance with designing your product, we can help.

Testing Equipment & Certifications – for access to international markets

If you plan to sell your product in Europe, Australia and Canada, you may need to get your product tested and certified to gain access to these markets. For example, the European Economic Area requires that products have CE registration. Similarly, in Australia you must have C-Tick testing or RCM certification for electronic products. In the USA, you may need to register with the FCC or UL depending on your industry. Luckily, RSP has internal testing equipment and maintains relationships with globally recognized testing labs that can get your product tested and registered. The test labs require a product sample to test and register for various required certificates.

RSP has the knowledge and ability to make sure your product is ready for the environment it will be used in. Call us today no matter where you are in the process!