Tactile keypads are simply keypads that have been specifically designed to give feedback to the user upon actuation. For example, when a button is pushed on a non-tactile keypad, the user’s finger presses against the visual representation of a button. The user does not know at what point they have actuated the button unless there is some type of visual signal. On the other hand, a tactile keypad provides a ‘snap’ feel or ‘click’ providing the user haptic feedback. This feedback lets the user know that they have actuated the keypad.

How does a tactile keypad work?

RSP manufactures several standard constructions of keypads that offer tactile feedback.

Silicone Keypad with Carbon Contacts: The silicone keypad is mounted above a flexible circuit or printed circuit board. On the bottom of the silicone are plungers with printed conductive carbon or carbon pills. The tactile feedback is provided when the webbing around the key collapses and creates a ‘snap’ feel. The carbon then touches the lower circuit and the key is actuated. The key returns to its original position when the finger is removed, ready to be actuated again.

Silicone Keypad with Metal Dome: In the above construction, the carbon is removed from the silicone and a metal dome is placed between the silicone plunger and the flexible or rigid circuit below. The metal dome provides both tactile feel and can even provide an audible ‘click’ upon actuation.

Membrane Switch with Polydome: Molded polyester domes (polydomes) are formed into the upper circuit or the graphics layer. No additional material is required and individual domes do not need to be placed for each key. Generally these domes are considered for large quantity orders to reduce costs.

Membrane Switch with Metal Dome: Stainless steel domes are commonly used in small to medium quantity jobs. They offer the longest actuation life and a better tactile feel than polydomes.

RSP maintains a significant inventory of domes ranging in size, shape and actuation force.

Our engineering staff will provide expert advice on the dome type best suited for your application.

What are benefits of using these in production?

On a non-tactile keypad, the user only knows that the button has been actuated when the device performs a function. This can lead to confusion about whether or not a button was pushed hard enough or correctly, which may lead to errors such as repeated unnecessary actuation. A tactile keypad avoids this confusion by having the button snap back after being actuated. This force is felt on the finger, and in some cases can produce a noise such as a click to further verify that the button was actuated. Apart from avoiding confusion, these keypads are preferred for other reasons including simple user experience (UX). UX is very important for consumer products, so that the consumer has an enjoyable time actuating your product. This can also help the customer understand the product more intuitively.

What products use this technology?

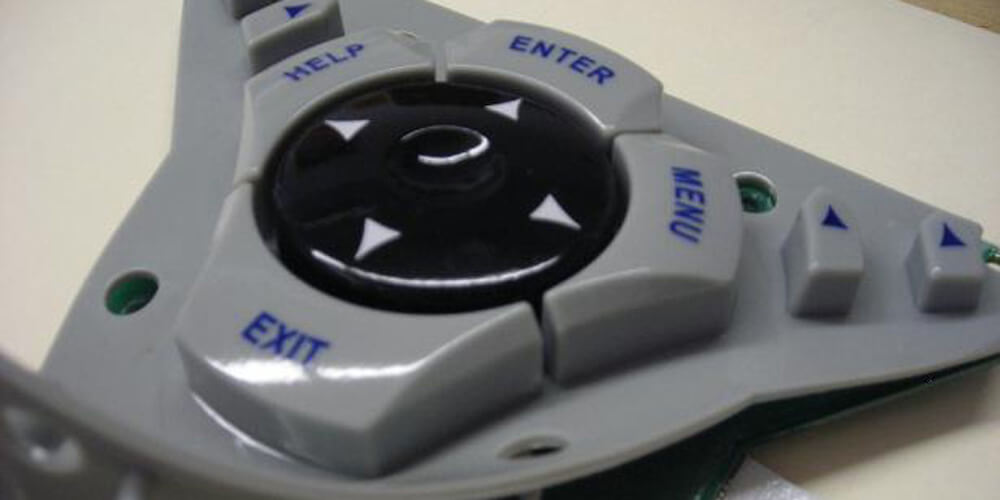

Virtually any keypad can incorporate this technology, and you’ve no doubt used hundreds in your life. This technology is used frequently in industrial and consumer applications, some examples are shown below in pictures.

If you would like to receive a sample pack from our sales team, give us a call at 1-866-329-1804 or email [email protected]

RSP Inc is a full turn-key contract manufacturer with over 50 years of experience. We can take your product from an idea all the way to a finished retail product with logistics and order fulfillment. The only limit is your imagination so dream big!

Case Study Example

A new client approached RSP to help improve an existing membrane switch design. The switch was used on construction equipment and was not holding up in the field as long as the warranty period causing a high cost in maintenance. The client sent us failed units which appeared to be of good quality construction but were showing signs of abuse from heavy use. RSP asked if we could observe the product use in the field and we went to visit a customer utilizing the switch.

We quickly were able to see that the switch actuated mechanical arm that had a delayed movement. Essentially, the switch user would attempt to actuate the arm and not get any immediate feedback. When this happened, they would press the switch multiple times and press forcefully to compensate for the lack of feedback. RSP suggested that the key be made larger to help the user locate the key and also integrate a large tactile dome in the construction to provide tactile feedback to the user. After manufacturing prototypes for field testing not only were the switches holding up longer but there was also improved operator satisfaction using the product and reduced maintenance costs.